Vintage

Car Work

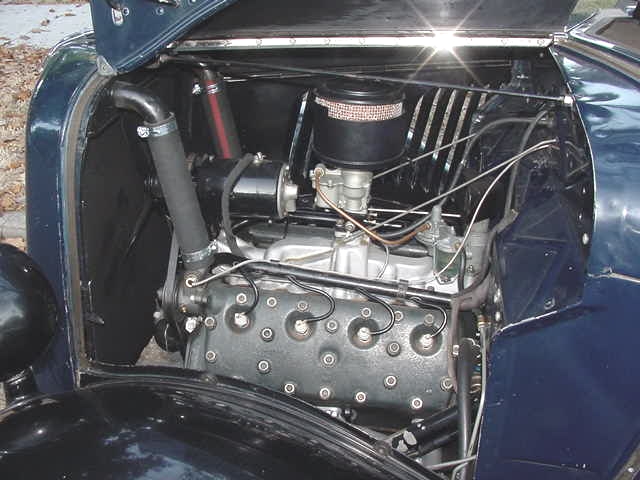

1930

Pierce Arrow

Bill found this car in San Jose about ten years ago or more. We had it

delivered to his home then did some initial service work to

get it

running better. Because of interests and calls in other areas of Bill's

life his Pierce Arrow went back into storage for several years. Bill

kept learning about his car and buying parts on eBay (a lot of parts)

until his time

demands allowed us to pick up where we left off. The engine had a blown

head gasket and Bill worried about the stock oil pump exploding (made

from pot metal and a known weak link) so I had him obtain a replacement

brass pump and made a new pump drive. We changed the head gasket and I

surfaced his head. I thought there was something wrong with the gasket

fit which turned out to be a mismatch between engine and head series.

We've put it back together while he looks for a correct head (a correct

spare came

with the car, but it's in very poor shape from a prior crack repair). I

also gave the engine a minor tune up. Bill changed his fuel tank and

lines, ignition coils and tires. I redid his steering and clutch

adjustments. There is always a part of Bill's character that wants to

Hot Rod anything he owns. Somewhere along the way he found a two BBL

manifold and then bought a bunch of updraft "U" and "UU" series

carburetors so I could to try and assemble a working combination. I

cannibalized a half dozen carburetors to perhaps build one serviceable

unit. It is heart breaking and expensive to have to winnow through

boxes of junk to find a couple of decent parts but that is the vintage

car restoration process sometimes.

The 2 BB manifold was

in poor condition; having cracked

porcelain and significant warp, a frozen heat riser and

excessive corrosion.

To restore the manifold I

sandblasted it,

then used porting and

polishing techniques on the exterior surfaces to prepared it for being

re-coated with new porcelain. Old cast iron is very brittle. With this

two piece manifold (separate intake and exhaust castings) alignment

when machine work is done becomes critical. Several cracks appeared

during the restoration process so I determined to stress relieve both

castings and straighten them as a unit, and weld repair the exhaust at

the same time. Then I'd re-evaluate machining. I fabricated a

very heavy (about 65 lbs) restraint bar with steel dowels to simulate

mounting alignment locations. Then I added bolts to restrain manifold

movement in "wrong" directions while allowing movement toward being

flat and correctly aligned. I delivered the whole manifold and fixture

to Gary and Guy Reed at Lock-N-Stitch

in Turlock, CA. for preheating, welding, and post heating at their

facility. They did a great job so I finished porting inside, made a new

heat riser shaft bushing, a new gasket pack for the plenum, and did a

final fit of the manifold sections. I then machined both manifold faces

in one set up. I'd contacted

Tom Sparrow at Prairie Auto Porcelain (17250 Cannon City Blvd.

Faribault, MN. 55021. Tom's cell is 507-581-9887) about re-firing

Bill's parts so they were ready to finish the

job. I shipped the entire manifold and assembled restraint bar to use

as the manifolds were porcelain fired. It came back looking wonderful

and straight as an Arrow. We also thermal barrier coated inside the

manifold surfaces to prevent heat from entering the old iron. This job

was really expensive but Bill feels it is a rare part, so justified.

To restore the manifold I

sandblasted it,

then used porting and

polishing techniques on the exterior surfaces to prepared it for being

re-coated with new porcelain. Old cast iron is very brittle. With this

two piece manifold (separate intake and exhaust castings) alignment

when machine work is done becomes critical. Several cracks appeared

during the restoration process so I determined to stress relieve both

castings and straighten them as a unit, and weld repair the exhaust at

the same time. Then I'd re-evaluate machining. I fabricated a

very heavy (about 65 lbs) restraint bar with steel dowels to simulate

mounting alignment locations. Then I added bolts to restrain manifold

movement in "wrong" directions while allowing movement toward being

flat and correctly aligned. I delivered the whole manifold and fixture

to Gary and Guy Reed at Lock-N-Stitch

in Turlock, CA. for preheating, welding, and post heating at their

facility. They did a great job so I finished porting inside, made a new

heat riser shaft bushing, a new gasket pack for the plenum, and did a

final fit of the manifold sections. I then machined both manifold faces

in one set up. I'd contacted

Tom Sparrow at Prairie Auto Porcelain (17250 Cannon City Blvd.

Faribault, MN. 55021. Tom's cell is 507-581-9887) about re-firing

Bill's parts so they were ready to finish the

job. I shipped the entire manifold and assembled restraint bar to use

as the manifolds were porcelain fired. It came back looking wonderful

and straight as an Arrow. We also thermal barrier coated inside the

manifold surfaces to prevent heat from entering the old iron. This job

was really expensive but Bill feels it is a rare part, so justified.

.

.

Bill has moved out of

the area and made arrangements to

disassemble his whole car at his son's shop to repair interior damage

and prepare it for club and show uses. This manifold will be stored

until used in it's final assembly.

Tom

is a collector who likes to drive and

use his vehicles. He has various automotive interests but likes 1930's

to 60's vehicles. This Cadillac reflects restoration work in other

shops before it came into Tom's garage. Tom wanted to freshen

the car's looks and correct minor deficiencys so it would be fully

functional for daily use. He has an interior man, and a paint man, but

needed me to do a gig list of about twenty mechanical and electric

items.

The car became registered for the Palo Alto Concors 'de Elegance and

then was selected to be the "cover car" on the show programs. Cadillac

was the featured mark that year so suddenly some pressure was on to

make this car as nice as it could be without redoing anything in a

major way. I was tied up on other projects and nearly didn't do my part

in time. As it turned out I did my mechanical and electrical repairs

after final detailing was complete. That was nerve wracking because I

had to work under the dash, undercarriage, and hood without soiling or

disturbing anything I couldn't re-clean or re-adjust.

I finished the day before the show and had an evening to drive around

and enjoy this wonderful piece of automotive history. Tom invited me to

the show to be available for any last minute issues and see the judging

committee work. I had an unlimited pass so this photo was taken from

behind the awards ramp looking out of the patrons tent. Tom received

the Manufacturers Award Trophy and Best in Class Trophy with his car

that year. He kept it for awhile and I did some service work on it

before it was sent on location for a movie shoot. One of the movie crew

fell in love with it and after buying it from Tom exported it to

Belgium. We hear it is quite popular over there too.

Leo's

1935 Ford

Leo is a really nice fellow.

He's quiet, knowledgeable, has a great

sense of humor, and loves restoring old farm equipment, pre-war

aluminum trailers, and Bugatti's. He drives and uses nearly everything

he works on so when he wore this pickup truck out it was no surprise to

the friends who know him. Nor was it surprising when several of them

helped Leo take his truck apart for restoration and "up

dating".

They are a great bunch of guys having a good time in their retirement

years. Soon a great used engine was located and checked out and set

into place. The chassis was worked over and some accessories, lights,

horns, and an electric fuel pump were bolted into place. Then Leo

called me and requested time in my shop so I could convert it to a 12

volt, negative ground system..... It turned into a rather complete

re-plumb, re-wire, vehicle assembly project because almost all prior

assembly work which had been done was more on a "trial fit" basis

rather than "finished". Some items of special note are an override

circuit to engage the fuel pump to prime the engine after prolonged

parking and a shut down circuit if the oil pressure fails. His truck

has thermal barrier coated headers and thermal insulation on the cab

floor. Leo wanted a sound deadened cab so acoustic matting went into

the headliner, rear cab, and under dash area. We wanted a "clean"

firewall look so many components that had gathered there were relocated

under the dashboard. His flat head is

mildly

warmed up with dual exhaust pipes, an aluminum manifold and careful

selection of internal parts. I added an external oil filter remotely

mounted under the left hand fender behind a custom rock guard / splash

shield.

The truck still has mechanical brakes and an original transmission,

drive shaft, and rear axle. Leo tows a small trailer to various meets

and shows all over the state and nearby out of state

locations.

mildly

warmed up with dual exhaust pipes, an aluminum manifold and careful

selection of internal parts. I added an external oil filter remotely

mounted under the left hand fender behind a custom rock guard / splash

shield.

The truck still has mechanical brakes and an original transmission,

drive shaft, and rear axle. Leo tows a small trailer to various meets

and shows all over the state and nearby out of state

locations.

His daily use of the truck

makes cosmetic issues secondary to

functional ones. It makes quality repairs, adequate vehicle inspection,

and complete service mandatory. Just like in the old days.

Race

boat "Miss Comet"

This is another one of Tom's interests, old wooden boats. He has

several and this one was rescued from the fate of disuse and decades of

prolonged storage. His family and craftsmen from Sierra Boat Works,

Lake Tahoe, CA. worked many, many hours to refinish the hull and

restore original fittings. The history of the boat as a racing design

with unusual center steering and dual aircraft throttles is

distinctive. After restoration the boat was entered in the annual

competition at Lake Tahoe and took first place. However it had several

functional issues. The 6 volt electrical system had been retained and

after winning the Tahoe show Miss Comet was again unexpectedly stored a

couple of years. Tom wanted to start using the boat again for the

summer of 2004 so I was asked to get her running, figure out why the

electrical system kept failing, and service the engines for a seasons

trouble free boating. Miss Comet has twin vintage Chrysler

Hemi

engines and differential throttle steering for low speed maneuvering.

Then the throttles are locked when the center rudder becomes effective

at high speed. Cooling water is pulled from the lake. Wet sump oiling

and wet manifolds

are

typical marine equipment. Because the men who rebuilt the engines and

installed them in the hull died just after completing their work

details like water and fuel drains, electrical circuits, fuel

management provisions and procedures for dry dock testing all had to be

figured out by inspection. It turned out the boats fuel pumps had an in

line restriction in one pump and a suction side air leak in the other.

The batterys were of insufficient ampere hour capacity to start a

warmed up Chrysler and the generators were geared too slow to recharge

them. That had lead to the regulators being miss adjusted. A small

water pump leak that kept the keel area wet had deteriorated two

electrical disconnect switches hidden under the hull ribbing spars. It

was quite an adventure to figure out which problem was the pivotal

problem preventing the boats operation.

are

typical marine equipment. Because the men who rebuilt the engines and

installed them in the hull died just after completing their work

details like water and fuel drains, electrical circuits, fuel

management provisions and procedures for dry dock testing all had to be

figured out by inspection. It turned out the boats fuel pumps had an in

line restriction in one pump and a suction side air leak in the other.

The batterys were of insufficient ampere hour capacity to start a

warmed up Chrysler and the generators were geared too slow to recharge

them. That had lead to the regulators being miss adjusted. A small

water pump leak that kept the keel area wet had deteriorated two

electrical disconnect switches hidden under the hull ribbing spars. It

was quite an adventure to figure out which problem was the pivotal

problem preventing the boats operation.

Gary Hubback and I worked out a cooling system modification so we could

fire the engines while the boat was trailered. We wouldn't run the

props or transmissions because Miss Comet's hull changes

shape if

not wet and floating causing prop shaft angles to exceed design limits.

My son Daryl and I figured out the fuel system and finally fired the

engines. Then trouble shooting the generators and batterys was pretty

easy. I fabricated period correct battery boxes for industrial sized

batterys and fixed the various switches and connectors. I replaced a

few things here and there while waiting for new generator pulleys.

Eventually the boat was ready to re-float and go on shake down runs. We

made a long weekend trip to perform those adjustments and took the

first photo in this set while leaving the harbor area of Serra Boat

works. Unfortunately a bad transmission kept us from approaching the

boats top speed. I hear it's a hair under 100 mph. A few months later

the transmission was fixed but the season was over by then so Miss

Comet went back into storage. She was sold in 2006 to an Eastern buyer.

1949 Ford Convertible. Tom

knew of this car for a number of years before acquiring it from the

east coast. It was restored back there and came here with a fairly

short completion item list. It is a V-8, radio, heater, manual

transmission convertible that has remained very stock. Gary Hubback

serviced the brakes and suspension at his shop. After that

Tom

asked me to repair the drive shaft, replace the transmission, and

rebuild some items under the hood. I detailed the Flat head

engine and re-plated a few brackets and throttle linkage parts.

Overhauling Tom's convertible top pump was a bit more challenging but

turned out well. I also rebuilt the shift linkage, installed a few

missing bolts, and stamped a new ID plate for his firewall. I repaired

his trunk lock / handle / latch assembly while keeping the original

key. I mixed up a bottle of touch up paint for future use in case door

nicks occur. It was a fairly typical potpourri list for a newly

acquired vehicle.

Tom

asked me to repair the drive shaft, replace the transmission, and

rebuild some items under the hood. I detailed the Flat head

engine and re-plated a few brackets and throttle linkage parts.

Overhauling Tom's convertible top pump was a bit more challenging but

turned out well. I also rebuilt the shift linkage, installed a few

missing bolts, and stamped a new ID plate for his firewall. I repaired

his trunk lock / handle / latch assembly while keeping the original

key. I mixed up a bottle of touch up paint for future use in case door

nicks occur. It was a fairly typical potpourri list for a newly

acquired vehicle.

These are photos of the convertible top pump before and after

rebuilding. Quite a few small parts were located at HYDRO-E-LECTRIC in

Florida and installed here. We were lucky that the switch assembly

cleaned up as they are quite rare. Royal Brass in San Jose, CA. made

new hoses with fittings similar to OEM . An N.O.S. transmission

assembly was found at All Ford in Campbell, CA. still in the original

crate.

This shoe box Ford's under hood area looks just as nice as the vehicles

exterior. Somebody had already started with late model Ford "blue"

paint on the engine so we stuck with it. The blank area on the left

firewall is where Tom's top pump mounts. It is a fully rebuilt pump,

but non-functional in this installation because of the risk brake fluid

might leak and ruin adjacent paint work. A new style after market pump

has been mounted in the truck to actually operate both convertible top

hydraulic cylinders. I've driven this car quite a bit. It has very

comfortable seating, easy steering, and adequate power. It is easy to

understand why it was such a sought after car when Ford started

production of them after WWII.

1932 Pontiac Convertible.

This is the last of Tom's cars I'm going to post. It's a

Pontiac

he keeps just for fun and he drives it on sunny days to work or on

errands. I've done some regular maintenance, a few repairs, and

modified a couple of items for him. An interesting item is the windup

clock in the rear view mirror.

I reproduced the Indian Head nickel shifter ball for this car and added

the side glass wind deflectors for Tom. This car is equipped with an

original drive train, radio, heater, and "touring" items like wipers

and turn signals. The rumble seat frame had been upholstered upside

down and latch assembled incorrectly. That was hard to figure

out, but when done right allowed my son to install a girl friend in the

rumble seat. This is a pleasantly intimate car when the top is up. It

is a car in which one can sit well and drive very easily.

Radiator Cap Hood

Ornaments. These hood ornaments represent about four years of

collecting parts and pieces by the owner from various auctions, club

functions and museum sales. My task was to fabricate functional

radiator caps from his parts then mount ornaments to the caps.

A purchased reproduction cap had the parts shown in the left hand

column. I made additional parts and modified the supplied ones to

create a cap that would actually work. Those part are shown in the

right hand group. Stainless steel hardware was upgraded to improve

longevity, a spacer sleeve controlled clearance between two wave

washers

which allowed the cross arm to "float" improving engagement with

the radiator's filler neck. The cross arm was forged to increase its

arm

strength and a radius profile added to the leading edge for better

engagement. A brass

gasket support ring was fabricated to center and provide appropriate

gasket compression. The centering body was turned down to match a

specific radiator filler neck size. Then the cap tops were center

drilled to allow a threaded mounting stud to protrude above the cap. In

all, about five hours of work per cap, or a bit more.

The right hand photo is of an original cap that was rebuilt with my

"extra parts". These had to be hand fit to the center because several

different dimensions for various makes exist. Then work to various

mascots began. This is an old metal cast version of a Lalique art deco

piece titled "Vitesse" a personification of speed.

In this case two small mounting screws were damaged and bent beyond

usefullness so they were removed and a single larger stud was cast into

the statue on her centerline. The statue base was milled flat and an

adapter ring obtained to adapt that flat surface to the radiator cap

crown. A rubber foam gasket was cut to provide sealing and a cushon for

the assembly. The mounted statue was then shipped to the

owner

who indexed it to his radiator filler and installed a

locating

pin I provided so in subsquent use it would remain pointed

forward.

This bowman is an orgional 1933 Pierce Arrow mascot. It had a corroded

mounting stud and minor damage that was corrected before it was mounted

on a cap.

It's base conture was correct to match a radiator cap crown so no

adaptor was installed. It is displayed here resting on a Lalique base

for photographic stability.

The next hood ornament shown below is a 1929 Pierce Arrow piece. It had

been broken at the bow arm wrist extension and repaired with soldered

potmetal then chromed over. Not very pretty, and the bow was gone. It

needed difficult and risk filled repairs. More importantly any method

to mount a bow was gone too. I removed most of the old repair and

reconstructed part of the finger detail with solder. I was able to

drill a mounting hole for a reproduction bow and arrow in the fist and

install them with clear epoxy. Not a perfect repair but much better

than it was and now quite presentable for a parade or motocade vehicle.

The last two mascots are reproduction Lalique items from 1928

titled "Victoire" and "Peacock Head". They were

provided to

me with original style mounting rings and a museum display

base.

My job was to fabricate illumination hardware and functional radiator

caps so they could be fitted to a vehicle. By making parts similar to

the ones used for the metal mascots both these

tasks were

completed in 2008-9. I believe both of these mascots will he shown at

the Pierce Arrow west coast national meet in 2009.

Back

to Fowler Main page

.

.