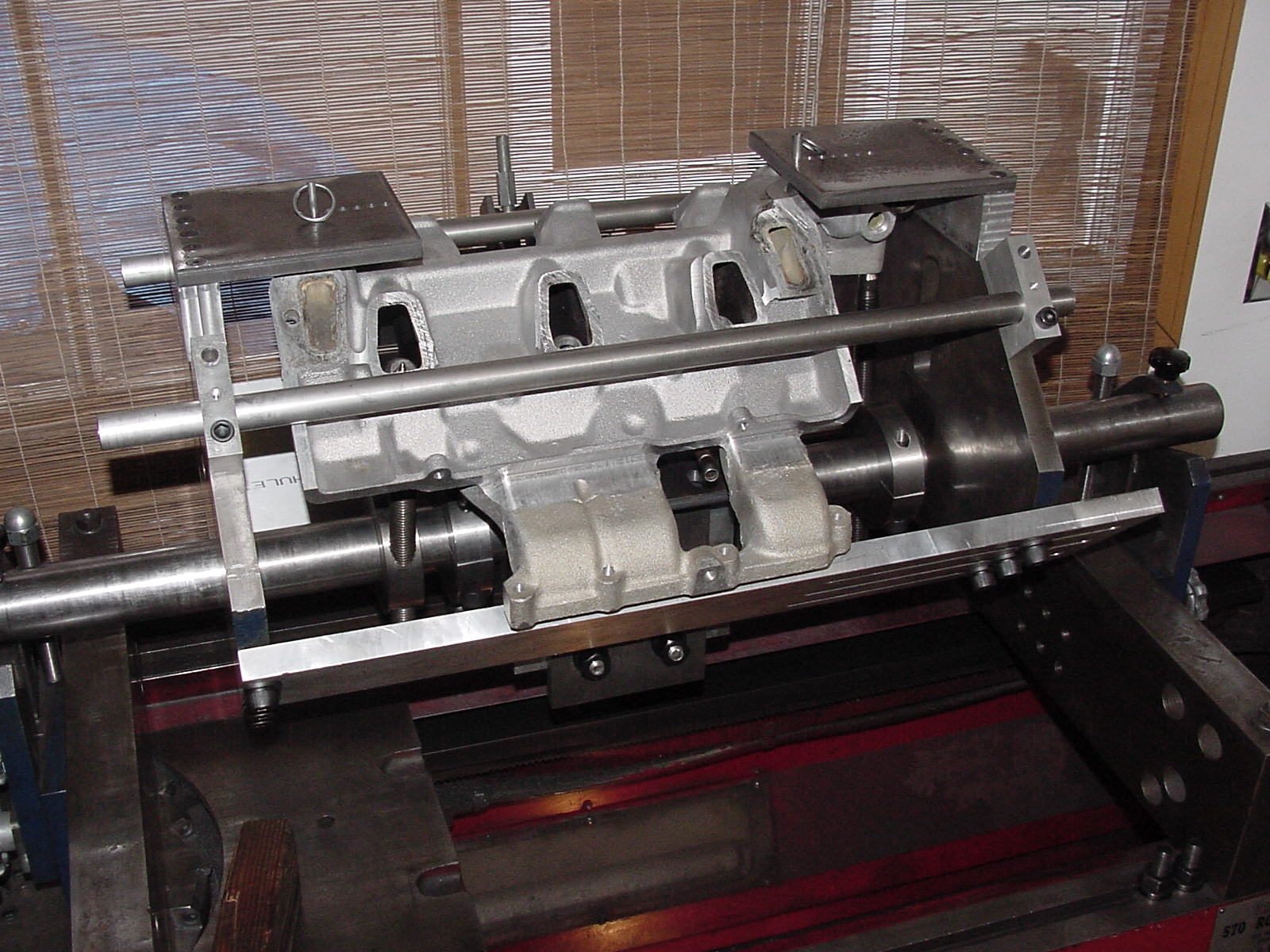

Resurfacing a 440 Chrysler

"RB" manifold to suit milled heads and

decked block at Wightman Engineering Services.

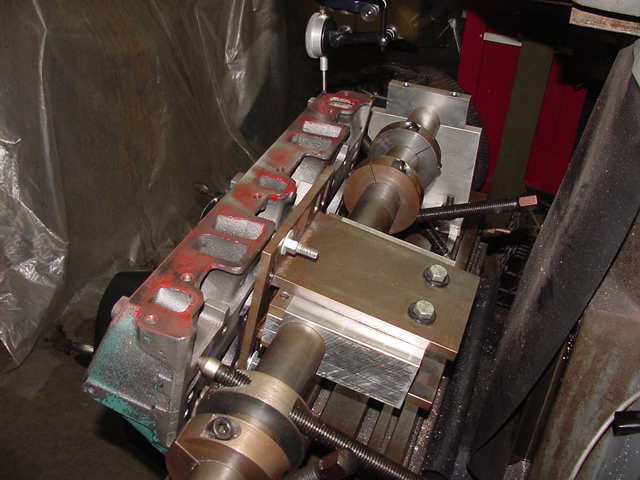

Re-cutting a weld repaired

vintage Corvette manifold for a

restoration job in an older Van Norman broach.

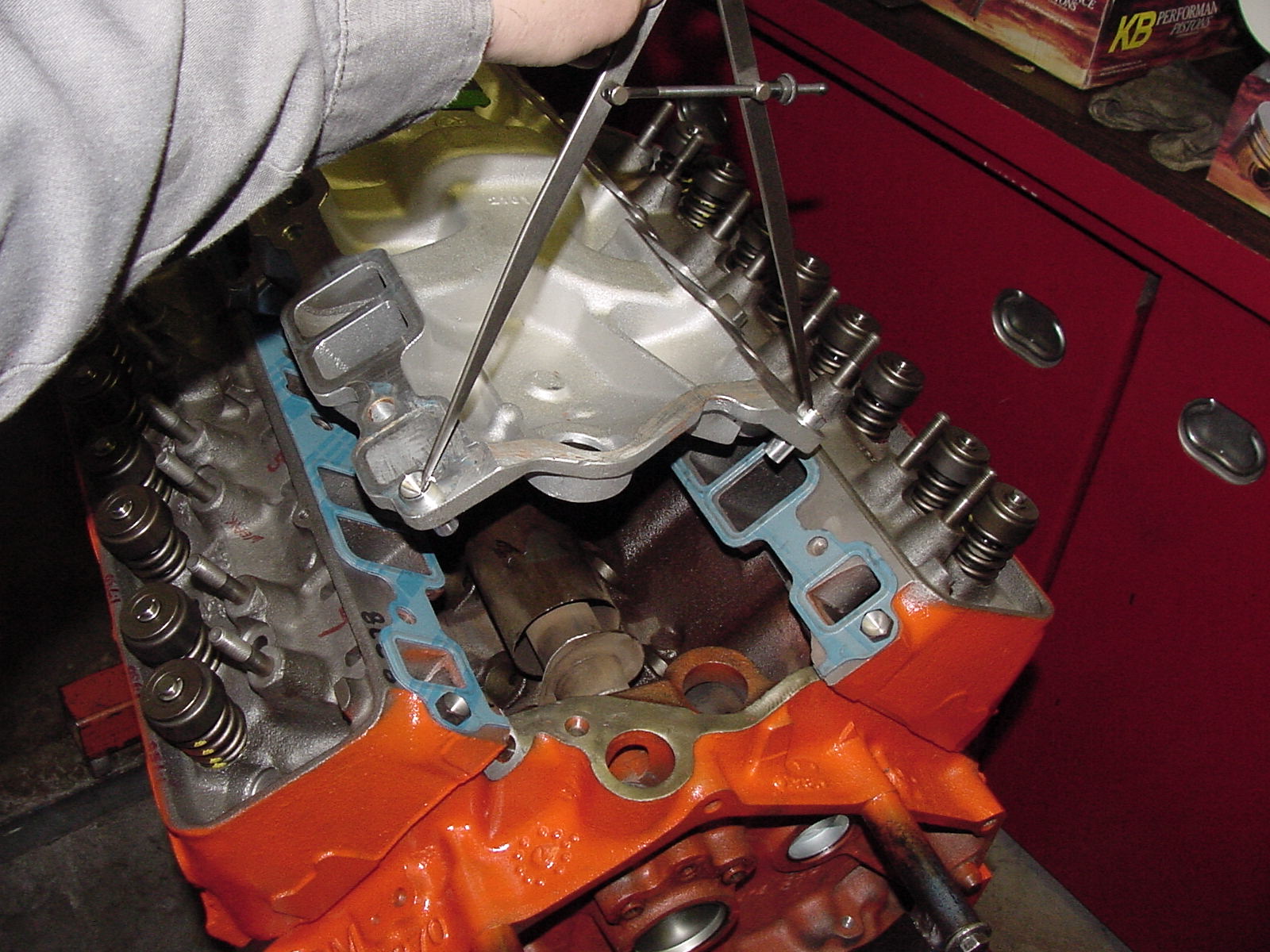

Aligning a late model 2.8

liter MPF Cadillac manifold prior to re-cutting

sealing surfaces for correction of vacuum and oil leaks.

Joe

Mondello and his shop foreman

inspect a new fixture I installed in his Rottler surfacing machine for

the Mondello Technical School.

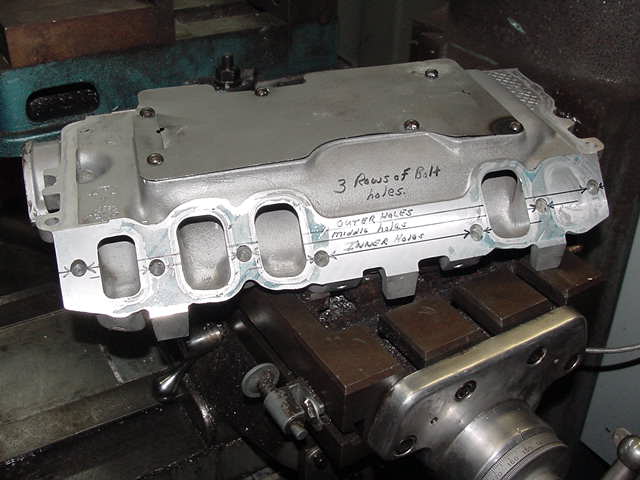

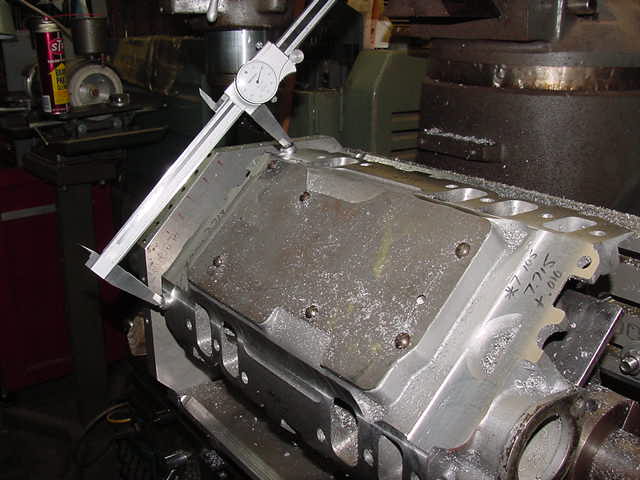

Ford

3.8 Supercharged manifold being

re-cut to suit a modified engine and checking bolt hole layout prior to

correction cuts at Fowler Automotive's shop in an older Bridgeport

clone mill.

An

Intake Manifold Resurfacing Fixture

can be configured as a rollover fixture to recut the head side of a

sealing surface, then hold the head while being machined for screw in

studs and guide plates in one set up. This uses no additional parts or

jigs than those supplied with an original fixture purchase. When

combined with a BHJ torque plate secured between the head and fixture,

which has BHJ's precision located dowel pin option, production runs of

corrected and modified heads becomes very fast and accurate.

The

measuring jig and bolt system is very easy and accurate to use. It can

be

implemented when the manifold is still in the fixture so a job can be

checked at a midpoint to assure a good fit, or after machining for

quality control. It can be used just as effectively before a manifold

is worked on to pre-plan stock removal.

Back to Fowler Main

page